NREL Connects EVs and Grid Integration

January 31, 2013

Enlarge image

Enlarge image

NREL scientist Michael Kuss of the NREL Electric Vehicle Grid Integration Team reads data from test electric vehicles at the Vehicle Testing and Integration Facility (VTIF).

Credit: Dennis Schroeder

Credit: Dennis Schroeder

Engineers working at the Vehicle Testing and Integration Facility (VTIF) enjoy a stunning view of the Denver skyline. However, some days the view includes Denver's 'brown cloud' — air pollution caused in part by vehicle emissions. While disheartening, the brown cloud helps the engineers focus on future technologies that will drastically reduce — and ultimately eliminate — those emissions.

Researchers at the U.S. Department of Energy's (DOE) National Renewable Energy Laboratory (NREL) are advancing a more sustainable transportation future by incorporating advanced electric vehicle technology, expanded use of renewable energy resources for vehicle charging, and grid integration.

"Our goal is to target the key innovations necessary to accelerate the rate of adoption for electric drive vehicles," said Bob Rehn, group manager for testing and analysis at NREL's Center for Transportation Technologies and Systems (CTTS). "In addition, our efforts are focused on scenarios that will incorporate expanded use of renewable energy resources to charge those vehicles."

The Right Tool for the Job

Enlarge image

Enlarge image

Denver's 'brown cloud' (seen here in the background) is motivation and inspiration for the NREL researchers working on cleaner vehicle technology at the VTIF.

Credit: Dennis Schroeder

Credit: Dennis Schroeder

The VTIF, which has been in operation for just over a year, was built with a specific focus on testing electric vehicles, charging options, and grid integration, all of which are critical for expanded transportation infrastructure around plug-in electric vehicles (PEVs).

"There are a lot of entities investigating components of electric vehicles, grid integration, or infrastructure," said NREL Vehicle Systems Engineer Mike Simpson. "There are very few places looking at how they all come together as a much larger, connected system. This facility was designed from the ground up to specifically address that intersection point."

Capabilities at the VTIF include vehicle energy management within smart grids, vehicle charge integration with renewable energy resources, bi-directional vehicle charge testing and demonstration, and vehicle thermal management. Four test bays at the facility allow for multiple tests to be conducted at once in controlled environments and can accommodate a wide variety of vehicles, including one test bay built specifically to conduct testing on heavy-duty vehicles. An upcoming addition to the facility is an 18-kilowatt solar array, which will be tied directly to vehicle charging and will allow researchers to do expanded work around the use of solar energy to charge electric vehicles within microgrids.

Better Charges and Better Grids

Further advances in how electric vehicles charge — and how they interact with power grids while charging — is critical to the future deployment of PEV technology. Much of the work being done at the VTIF is centered on this effort and is being done in collaboration with efforts at NREL's new Energy Systems Integration Facility (ESIF).

"We're bringing together systems that have never had a reason to talk to one another before," Simpson said. "There are enormous opportunities to bring value to this intersection of vehicle and grid, which will increase adoption of these technologies."

Key VTIF research is focused around smart charging. Smart charging involves direct communication between a vehicle and a charging station, bringing information that allows grid operators, charging stations, and potentially the vehicles themselves to decide when and how to charge the vehicle. The average electric vehicle sits, undriven, for 20 to 22 hours out of a day, but only takes 2 to 4 hours to charge using current technology. This makes an electric vehicle a very flexible load on the power grid.

This flexibility creates opportunities for NREL researchers focused on smart charging applications that will leverage the most economical and environmentally sustainable charging options — all while still allowing for on-demand use of the vehicle by the driver.

A four-hour fill up doesn't quite compete with gasoline engines for on-the-road demand, so engineers are exploring scenarios for fast charging. A fast charge can potentially recharge an electric vehicle in 15 to 25 minutes if the battery is close to empty. This technology employs the conversion of alternating current (AC) grid power to direct current (DC) power, which can be delivered directly to the battery pack. This method allows for faster charges using smaller charging equipment.

Additionally, VTIF researchers are exploring opportunities for bi-directional charging. Bi-directional, or vehicle-to-grid (V2G), charging employs smart charging capabilities but also allows for the vehicle to discharge back to the grid, which turns the vehicle battery into a grid storage device. This capability is of particular interest when combined with microgrids. A microgrid is a potentially self-sufficient segment of the grid that is connected to the power grid at large but has the ability to provide and manage its own energy. In a future scenario where there may be variable production from intermittent renewable sources, readily available storage could buffer that variability. With bi-directional charging, electric vehicles have the potential to play that role, and the vehicle becomes an asset in a smart grid or microgrid. Particular areas of interest for this technology emerge around emergency backup power or the use of vehicle fleets for this purpose.

"We need to be exploring all of the different value streams to enable wider electric vehicle adoption and improved interaction with the grid," Simpson said. "We can implement all of these different tactics in harmony with one another here at the VTIF. It's a very exciting opportunity."

Expanding the Use of Renewables with the Green Signal

Enlarge image

Enlarge image

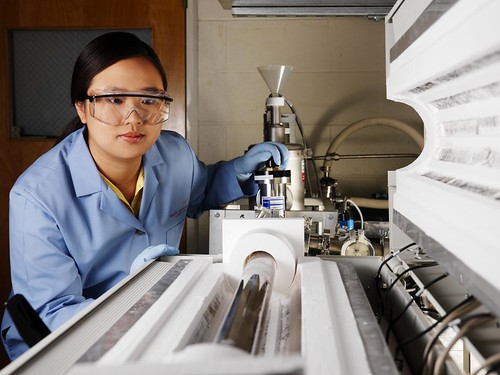

NREL Vehicle Systems Engineer Mike Simpson connects a direct current (DC) battery from an electric vehicle to a grid charging system that supplements the grid with stored electricity from the vehicle.

Credit: Dennis Schroeder

Credit: Dennis Schroeder

The next big step for PEVs is expanding the use of renewable energy as a resource for charging. This involves utilizing enhanced smart charging technology to charge vehicles when the most renewable resources are available on the grid — often at the lowest possible cost to consumers. NREL has developed a specific technique for integrating detailed real-time data into a charge management algorithm, referred to as the 'Green Signal.'

The Green Signal would monitor the availability of renewable resources, as well as utility market prices. It would charge the vehicle when the renewable resources are most available and at the lowest possible cost per kilowatt hour. This gives consumers the opportunity to 'buy low' when their electricity cost is low while at the same time maximizing the use of renewables. The technology also monitors vehicle use times to ensure that the vehicle is fully charged when needed.

NREL will be exploring the Green Signal in the coming years using a fleet of electric vehicles plugged into onsite vehicle charging stations, which have been equipped with modified software to add this functionality.

"It's an exciting opportunity to bring more renewables into the equation in a cost-competitive way," Rehn said. "This software will allow us to enhance charging with solar or wind when it is at a cost that is equivalent to, or less than, that of conventional sources. By having a fleet of vehicles, we will be able to investigate doing this at a reasonable scale, being able to control individual chargers and vehicles at different times as the available resource is available, and we'll be able to develop the algorithms needed to evaluate when and how it makes the most sense to utilize this charging method."

Expanding Vehicle Range with Enhanced Thermal Management

Enlarge image

Enlarge image

A car undergoes climate control analysis at NREL's VTIF.

Credit: Dennis Schroeder

Credit: Dennis Schroeder

Once an electric vehicle is charged and disconnected from the grid, the next important step involves maximizing the vehicle's range between charges. PEV range can be reduced 30% to 45% due to heating and cooling, so NREL engineers are investigating opportunities to change this dynamic and increase range via vehicle thermal testing and analysis.

"Our focus is on improving the thermal efficiency of efficient electric vehicles, with specific emphasis on climate control," said NREL Senior Engineer John Rugh, who serves as task leader for the vehicle thermal management work taking place at the VTIF. "The impact of climate control on an electric vehicle can be huge, and we are working with industry partners to conduct these tests and assess technologies that will reduce climate control loads for both heating and cooling of the vehicles."

These tests, which take place outside on the VTIF's test pad, involve two heavily instrumented electric vehicles. The instruments measure temperatures on the interior and exterior of the vehicles during a 'thermal soak' when the vehicle is sitting in a parking lot or during a cool-down cycle after the vehicle has been powered. The temperatures are fed into a data acquisition system and recorded for future analysis. In addition, an onsite weather station immediately adjacent to the vehicles provides accurate weather data.

"One of the biggest concerns with electric vehicles is range," said Rugh. "The battery of an electric vehicle is a finite energy source at the beginning of a drive, so reducing loads related to climate control allows more of the battery capacity to go toward vehicle range. If we can accomplish that while at the same time maintaining or improving occupant comfort, it can go a long way toward increasing the range of the vehicles and hopefully lead to expanded adoption of these vehicles by consumers."

Plugging Into our Transportation Future

NREL researchers are keeping their eyes on the future and how the VTIF's increased capabilities could impact how we power transportation.

"We're very proud of this new facility and the potential impact that it can have," Rehn said. "It gives us an opportunity, working in collaboration with our industry partners and DOE, to better understand how all of these issues work together. This will lead to putting more electric vehicles on the street with a reduced cost of ownership and will allow them to be charged using the maximum possible amount of sustainable energy resources."

Learn more about NREL's Center for Transportation Technologies and Systems and VTIF .

.

— David Glickson

Another Angle on Transportation Fuels Reduction — Heavy-Duty Vehicles

Enlarge image

Enlarge image

Tractor-trailer trucks undergoing thermal analysis at NREL's VTIF. The focus is on idle reduction for long-haul trucks, which use approximately 685 million gallons of diesel fuel in the United States each year for rest-period idling.

Credit: Dennis Schroeder

Credit: Dennis Schroeder

The focus is on idle reduction for long-haul trucks, which use approximately 685 million gallons of diesel fuel in the United States each year for rest-period idling. This is about 6% to 7% of their total fuel use. One of the primary reasons for this idling is operating climate control and cabin comfort systems when the truck is not being driven.

"We're helping the heavy-duty vehicle industry reduce their fuel use," said NREL Senior Research Engineer Jason Lustbader, task leader for the heavy-duty vehicle climate control work taking place at the VTIF. "Our goal is to achieve at least a 30% reduction in climate control loads for these trucks with a three-year or better payback period for the industry by 2015."

Using test truck cabs located on the VTIF outdoor test pad, researchers are investigating a wide variety of cab thermal management technologies in collaboration with their industry partners. Electronically powered idle-reduction climate control systems in the cabs allow the engineers to look at the impacts of different technologies on the climate control loads.

A specific area of interest is paint. Research has shown a significant reduction in power needed for rest-period climate control just by switching the cab color from black to white. Engineers are investigating advanced paints that may look one color but behave and perform thermally like a different color. This could potentially allow trucking companies more flexibility when selecting paint colors — without sacrificing efficiency. This advanced paint work is currently being quantified through modeling and additional testing.

Another focus of this work is advanced insulation for truck cabs. Working with industry partners, researchers have shown a 34% reduction in the electrical power required for air conditioning by using advanced insulation materials.

"The VTIF is a perfect location to do this work," Lustbader said. "The south-facing test pad has no obstruction or shading and was designed specifically to facilitate this type of cab thermal management research."

The opportunities for consumer benefit by reducing costs of long-haul trucking are significant. Almost everything we purchase, from groceries to office supplies to fuel for our own vehicles, arrives via truck. So reducing the transport costs in any significant way will have an impact on the cost of those goods.

"We have an opportunity to make a real impact with these projects, an opportunity to reduce our national level fuel use and impact how we're using that fuel, in a way that can have a direct positive impact for industry and consumers," Lustbader said. "And we get to do some really fun engineering, too, solving complicated problems and helping move solutions forward to the point where it makes good sense for them to be used in the real world. That's what this type of research is all about."